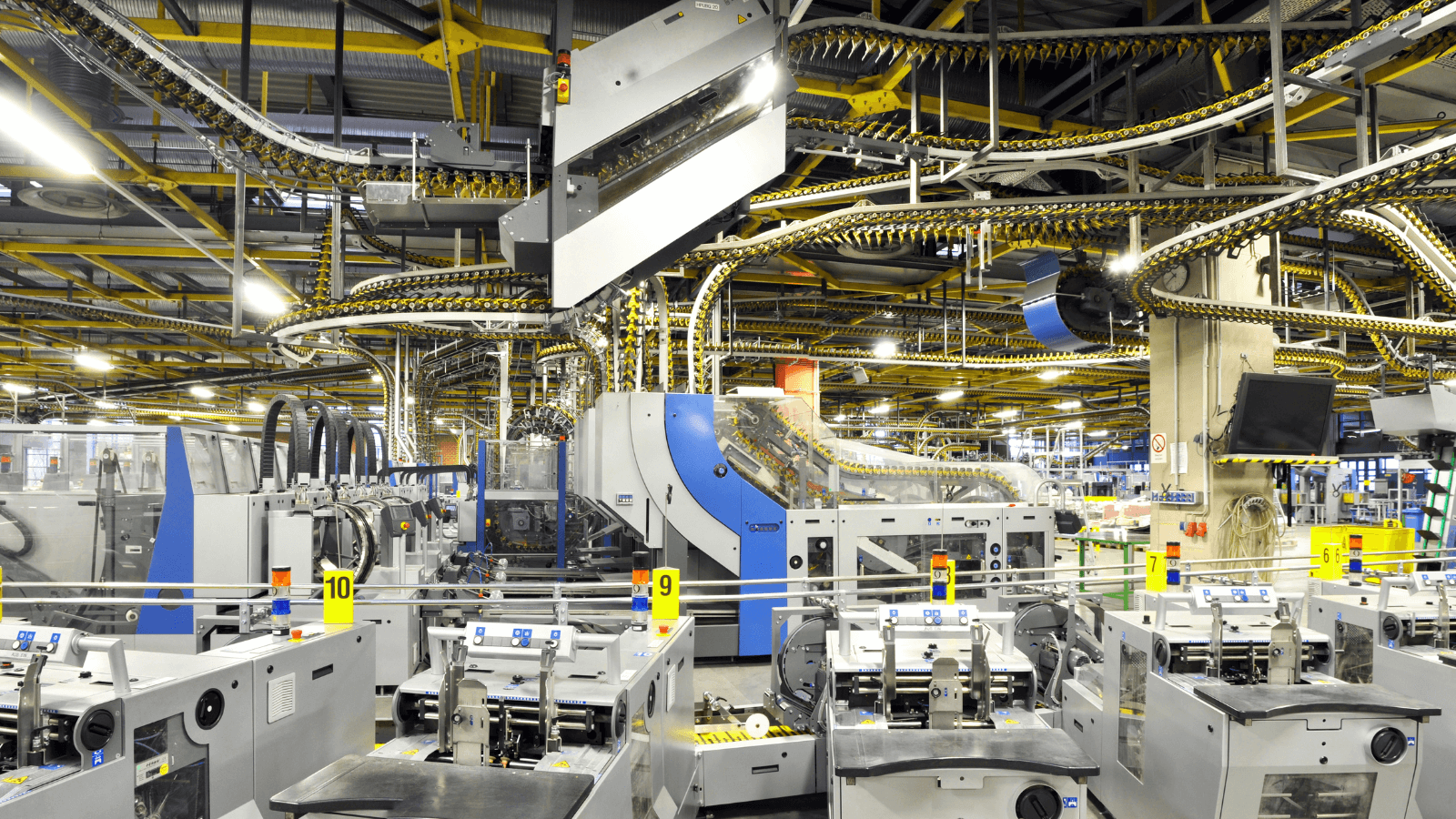

How Manufacturing Businesses Can Use Digital Technologies to Grow

The COVID-19 pandemic affected businesses across all industries. But when many companies had to close their doors while the country was on lockdown, numerous manufacturing businesses remained open. Some manufacturers were forced to change their business models entirely, and countless others had to adapt on the fly to adjust to fluctuations in demand, changes in buyer behavior, and new employee health and safety precautions.

Investing in Digital Technologies to Stay Competitive

As manufacturing businesses look to a future that will be significantly impacted by the effects of the pandemic, it’s critical to identify what needs to be done in order to stay competitive. Perhaps the most valuable lesson we can learn is the fact that the majority of businesses who’ve successfully navigated the COVID-19 crisis report having one thing in common: a range of technology-related capabilities that other businesses lack. Furthermore, a recent study found that those businesses who “experimented with new digital technologies during the crisis, and among those that invested more capital expenditures in digital technology than their peers did, executives are twice as likely to report outsize revenue growth than executives at other companies.”

Ways Technology Can Help Your Manufacturing Business

Here are 3 ways digital technologies can help your manufacturing business:

Automating tasks optimizes workflows, expedites processes, and reduces costs. If your manufacturing business is still using pen and paper and Excel spreadsheets to create monthly equipment status reports on KPIs, you’re probably not working at peak efficiency. Instead, consider implementing technology that will allow you to pull data from equipment and display it in real-time in a dynamic dashboard. Eliminating redundant processes like these will undoubtedly help you increase productivity.

- Digital Connectivity to Equipment and Assets

With COVID-19 and social distancing protocols affecting workforces in the manufacturing industry, having digital connectivity is of the utmost importance. It helps workers collaborate and communicate with each other and allows technicians to remotely monitor equipment for reliability. A recent article explains it like this: “Tools that connect workers both to other workers and to data will help manufacturers turn the data into actions that generate real value: Imagine an operator who wants to troubleshoot a piece of equipment, and can share real-time machine data with a remote expert to get precise guidance.”

Using technology such as artificial intelligence, machine learning, and cloud computing to analyze data from equipment will facilitate the implementation of predictive maintenance. This will help you reduce the instances of unplanned equipment outages and failures, minimize downtime, and save money.

What Financing Options Are There for Manufacturing Businesses Who Want to Invest in These Trends?

There are several different types of financing options available for manufacturing businesses looking to invest in digital technologies or simply interested in growth. We recommend contacting us to get a personalized recommendation for which financing solution, best meets your company’s needs. The most commonly recommended funding products for the manufacturing industry are:

- Small Business Term Loans

- Invoice Financing

- Equipment Financing

- Bridge Capital

- Business Line of Credit

Make the Most of Your Manufacturing Business

We’ve helped tons of manufacturing businesses scale up to the next level. Apply today and see what a difference funding can make. In manufacturing, keeping up with demand can be quite “demanding”, and products can be expensive to make. At SBG Funding, we offer financing solutions that give manufacturers the slack they need to succeed. No matter what you’re making, make sure you speak to us first!